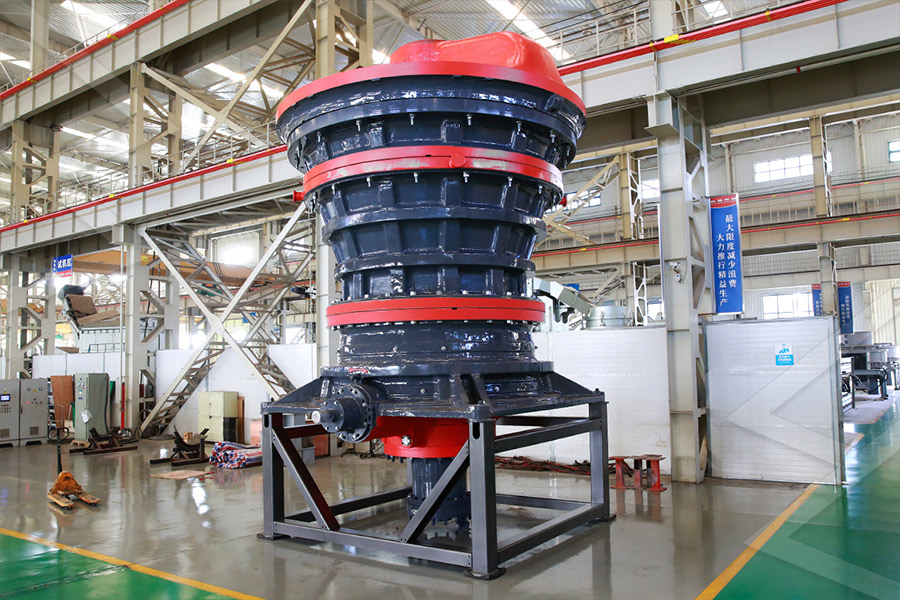

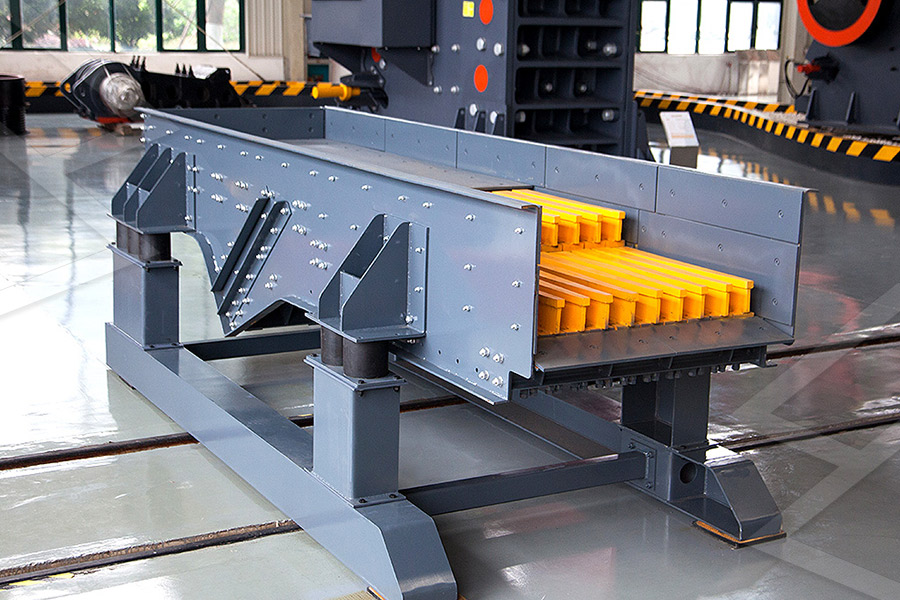

Finely Processed Cement Mill For Mining And Chemical Industry On Hot Sell

.jpg)

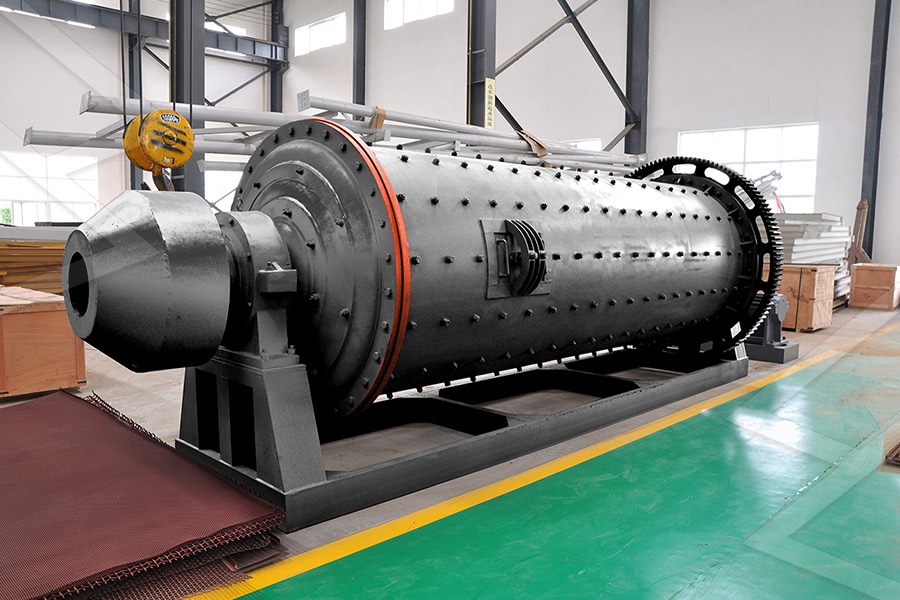

BALL MILLS Ball mill optimisation Holzinger Consulting

2021年3月12日 efficient grinding systems available for the cement and mineral industry, including vertical roller mills (VRM), highpressure grinding units (HPGR) or simple roller 2017年6月19日 The modular vertical roller mill for grinding cement raw material, cement clinker, and additives with an installed power of up to 12,000 kW was specifically designed to meet the Grinding process optimization IEEE XploreChina Cement Ball Mills wholesale Select 2024 high quality Cement Ball Mills products in best price from certified Chinese Ball Machine manufacturers, Cement Plant suppliers, wholesalers China Cement Ball Mills, Cement Ball Mills Wholesale, China Cement Mill wholesale Select 2024 high quality Cement Mill products in best price from certified Chinese Cement Mixer manufacturers, Grinding Equipment suppliers, wholesalers Cement Mill MadeinChina

.jpg)

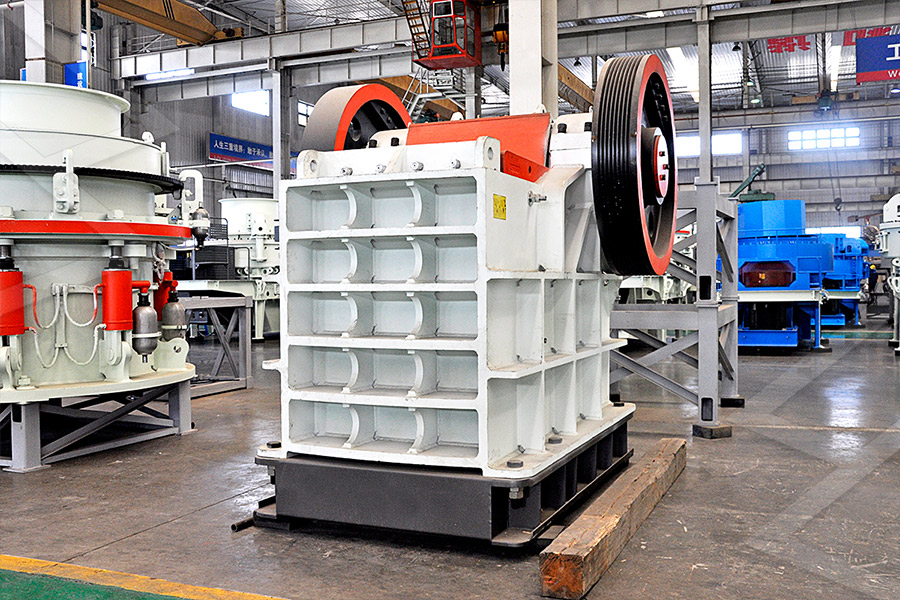

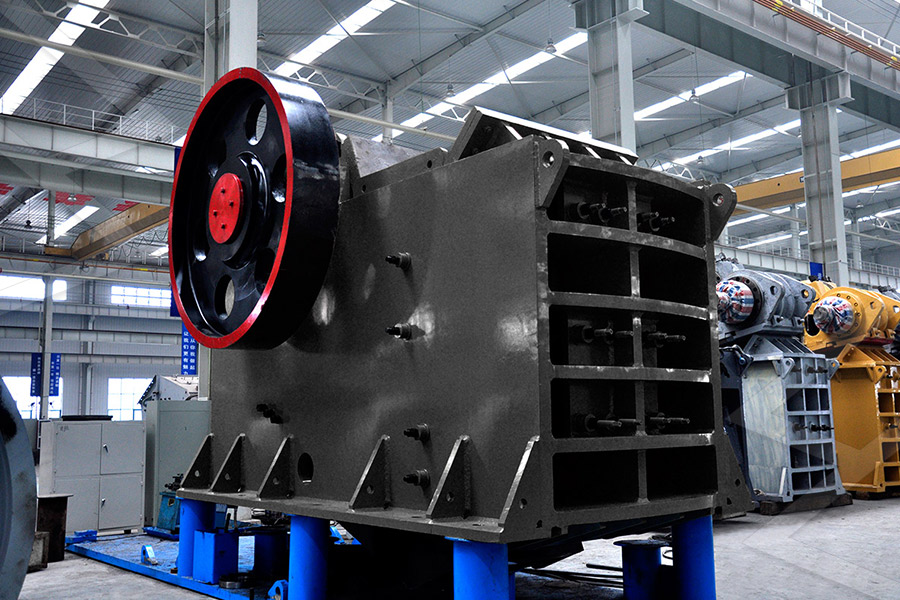

Cement Equipment cement Mill MadeinChina

China Cement Equipment cement Mill wholesale Select 2024 high quality Cement Equipment cement Mill products in best price from certified Chinese Machine Equipment Control 2010年3月27日 The three broad processes of cement manufacturing are: Raw milling — the preparation of the kiln feed Calcining and burning or clinkering — the conversion process that The Cement Production Process mcilvainecompany2021年1月1日 Estimating energy consumption in cement mills is critical for the cement industry Following data science practices and adopting machine learning (ML) technologies, we Machine learning applications and process intelligence for cement Our machines and processes for the cement and granulated blastfurnace slag industry Grinding of cement and/or granulated blastfurnace slag – Material separation in the filter The cement components are ground, dried, and Mills for cement and granulated blastfurnace

Ball Mill for Sale Cement Mining and Chemical

2024年3月22日 AGICO CEMENT is an experienced ball mills supplier, that provides types of ball mills, vertical roller mills, rod mills, and AG/SAG mills for cement, mining, chemical, and electric power industries Products2024年3月7日 J Res Technol Eng 4 (3), 2023, 161168 JRTE©2023 164 To improve energy efficiency and reduce fuel consumption, the powdered raw mixCement Manufacturing Process and Its Environmental 2019年7月31日 This review article explores the evolution of the Indian cement industry, air pollutants from the cement industry, social and environmental implications, satellite datasets, models used for (PDF) Environmental Pollution by Cement 2024年6月1日 This article covers the top 10 essential chemicals used in the mining industry in detail with their benefits and applications 1 Sodium Cyanide Cyanide is a critical chemical in the mining industry, particularly for extracting gold and silver It forms a complex with gold, allowing it to be separated from the oreTop 10 Chemicals for Mining Industry Camachem

.jpg)

Cement Production Demystified: StepbyStep Process and

2024年1月18日 The use of fossil fuels such as coal, natural gas, and oil is common in cement production, both as a fuel for the kiln and as a source of heat for other parts of the process which leads to CO2 emitted by combustionHowever chemical reactions happening in the kiln (calcination) are also responsible for up to 60% of the total of emissions of the 2016年3月1日 Saunders, A, ‘The highs and lows of India’s cement industry,’ Global Cement Magazine, March 2015; Saunders, A, ‘The cement industry of China ‘A new normal,’ Global Cement Magazine, JulyAugust 2015; Edwards, P ‘The rise and potential peak cement demand in the urbanized world,’ in Cornerstone, Volume 3, Issue 2, Summer 2015Coal for cement: Present and future trends Global Cement2017年6月9日 Generally, the uranium ore extracted from the mine is processed by an associated mill order to obtain yellow cake (uranium oxide) for export (Fig 10) This mining and milling stage generates significant amounts of mining waste and radioactive waste tailings, where most of the radioactivity of uranium ore due to uranium radioactive daughters Mining industry and sustainable development: time for change2022年1月10日 The required pace of transition means that the availability of certain raw materials will need to be scaled up within a relatively short time scale—and, in certain cases, at volumes ten times or more than the current market size—to prevent shortages and keep newtechnology costs competitive (see sidebar “Rareearth metals”)The rawmaterials challenge: How the metals and mining

.jpg)

How Does a Raw Mill Work in a Cement Industry

2024年2月23日 The operation of the cement raw mill is a critical step in cement production By grinding the raw materials into a fine powder, these powders can be more easily mixed with other cement ingredients and burn more evenly during the cement clinker process Therefore, the efficient operation of the cement raw mill directly impacts the production efficiency and quality 2024年9月26日 Ask the Chatbot a Question Ask the Chatbot a Question cement, in general, adhesive substances of all kinds, but, in a narrower sense, the binding materials used in building and civil engineering construction Cements of this kind are finely ground powders that, when mixed with water, set to a hard massSetting and hardening result from hydration, which is a Cement Definition, Composition, Manufacture, History,2021年3月3日 Cement is produced by a hightemperature (about 1500 °C) reaction in a rotary kiln of carefully proportioned and blended ratios of lime (CaO), silica (SiO 2), alumina (Al 2 O 3), and iron oxide (Fe 2 O 3)The production of cement is a chemical process requiring an accurate blend of the previously cited four key organic oxides and the limitation of several undesirable Cement SpringerLinkVarious ball mill machines, vertical roller mills and sag mills are widely used in the mining industry Grate ball mills and raw mills are mostly used for mineral processing in some enterprises of mining industries Wet ball mill and rod mill Ball Mill for Sale Mining and Cement Milling

Innovation in the Mining Industry: Technological

2020年7月23日 Innovation plays a critical role in the mining industry as a tool to improve the efficiency of its processes, to reduce costs, but also to meet the increasing social and environmental concerns among communities and 2024年4月24日 clinker are processed in the mill, divided into two stages: the grinding stage in chamber I and the milling stage in chamber II In the final stage, the cement is transferred to the separation stage, where the raw material is returned to the mill while the fine cement is stored in the storage silo [38, 40] 23 Cement Packaging and DispatchImpacts of Cement Production on the Environment with 2021年4月16日 The Jaypee Rewa Cement Cement industry, Rewa, Madhaya Pradesh is located between 24o 33’ North longitude and 81o 10’ east latitude and is situated at Jay Prakash Nagar 20km from Rewa Town of (PDF) A Review on Air Pollutants from Cement Industry and 2024年9月5日 All living things, including plants, animals, and humans, need water in order to live Even though the world has a lot of water, only about 1% of it is fresh and usable(PDF) Optimization of Chemical Engineering Processes in the Mining

Finely Processed Cement Grinding Mill For Mining And Industry

2021年11月9日 Finely Processed Cement Grinding Mill For Mining And Industry Finely Processed Cement Grinding Mill For Mining And Industry Micronizer Flow Chart Cement Mills Machinery Crusher Whether it is for investment or enterprise selfuse, ultrafine mill is the star and hot spot on the market So 1000 mesh, or even finer 1500 mesh, 2000 mesh, which 2023年6月15日 The cement industry plays critical role in any country’s development and economic growth Cement is extensively used in construction sector and infrastructural projects Abundant raw material availability, infrastructure demands, urbanization, and recent government initiatives—Atal Mission for Rejuvenation and Urban Transformation (AMRUT) project and Impacts of cement industry air pollutants on the 2020年1月1日 The demand for cement, which is one of the key components of concrete, is high in Ethiopia, but it is the most expensive and environmentally unfriendly construction materialAssessment on Cement Production Practice and Potential Cement 2014年6月10日 It begins with an overview of what cement is and how it is used to make concrete It then describes the industrial process for manufacturing cement, involving grinding raw materials like limestone and clay at high temperatures in a kiln to form clinker, which is then pulverized with gypsum to become Portland cement powderCement manufacturing process PPT SlideShare

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 processing and mining industry, metallurgy, cement production, chemical industry, pharmaceutics and cosmetics, ceramics, di fferent kinds of laboratory studies and tests2023年8月21日 • CPI LNVT Ball Mill: CPI LNVT is a renowned manufacturer of grinding equipment for the cement industry Their ball mills are widely used for grinding cement clinker, gypsum and other materials into a fine powder The Grinding process is a critical stage in cement 2020年9月8日 Mine tailings are the waste material that remains after the economic fraction has been extracted from the mineral ore Tailings consist of a slurry of ground rock, and water and chemical reagents that remain after processing The composition of mine tailings varies according to the mineralogy of the ore deposit and how the ore is processedCHAPTER II MINE TAILINGS 4 FACILITIES: OVERVIEW 3 2 Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by Raw mill Cement Plant

An extensive review on restoration technologies for mining tailings

2018年10月15日 Tailing, in context to mining, is defined as the waste or noneconomic byproduct generated during mining activities, processing of minerals, and other materials that contain small amounts of residual valuable minerals, chemicals, water, and heavy metals (Adiansyah et al 2015)Studies indicated that the process of mineral exploitation and 2021年9月15日 The mining and cement industries make significant contributions to the world’s emissions, so finding ways to decarbonise is essential to meeting global emissions targets The green transition is increasing the demand for metals and minerals that are needed to produce wind turbines, solar panels, electric vehicles, battery storage, and other How can we decarbonise the mining and cement industries?Adjusting mill parameters: Finetuning mill parameters such as mill speed, ball charge, filling ratio, and grinding media size can have a substantial impact on the grinding efficiency of the mill For example, a 10% increase in mill speed can result in up to 10% higher production rate, while optimizing the ball charge can lead to a 510% Cement Mill Optimization: Practical Strategies for Enhanced Introduction Greenhouse gas (GHG) emissions such as CO 2 from industry continue to rise worldwide despite efforts to decrease emissions, such as stated in the 2015 Paris agreement, which aims to limit global warming to 2°C and make efforts to limit it to 15°C (Jarraud and Steiner, 2014; IEA, 2017; Rogelj et al, 2018)The steel industry is one of the major emitters of Deriving Economic Potential and GHG Emissions of Steel Mill

Cement and Clinker Production by Indirect

Global cement production has reached 39 billion tons However, the clinkerization process, which is the basis of cement production, is responsible for an approximate annual global CO2 emission of 2 billion tons As part of CEMBUREAU’s 5C strategy, the European cement industry aims to achieve carbon neutrality throughout the cementconcrete value chain by 2050 This article is 2024年1月9日 The cement production process emits approximately 09 tons of CO 2 per ton of cement (Hasanbeigi et al 2010), accounting for about 5–8% of global CO 2 emissions and ranking as the secondlargest CO 2 emissions source (Mikulčić et al 2016; Kajaste and Hurme 2016)According to the Intergovernmental Panel on Climate Change (IPCC) report, the cement Carbon emissions mitigation methods for cement industry2024年3月22日 AGICO CEMENT is an experienced ball mills supplier, that provides types of ball mills, vertical roller mills, rod mills, and AG/SAG mills for cement, mining, chemical, and electric power industries ProductsBall Mill for Sale Cement Mining and Chemical 2024年3月7日 J Res Technol Eng 4 (3), 2023, 161168 JRTE©2023 164 To improve energy efficiency and reduce fuel consumption, the powdered raw mixCement Manufacturing Process and Its Environmental

(PDF) Environmental Pollution by Cement

2019年7月31日 This review article explores the evolution of the Indian cement industry, air pollutants from the cement industry, social and environmental implications, satellite datasets, models used for 2024年6月1日 This article covers the top 10 essential chemicals used in the mining industry in detail with their benefits and applications 1 Sodium Cyanide Cyanide is a critical chemical in the mining industry, particularly for extracting gold and silver It forms a complex with gold, allowing it to be separated from the oreTop 10 Chemicals for Mining Industry Camachem2024年1月18日 The use of fossil fuels such as coal, natural gas, and oil is common in cement production, both as a fuel for the kiln and as a source of heat for other parts of the process which leads to CO2 emitted by combustionHowever chemical reactions happening in the kiln (calcination) are also responsible for up to 60% of the total of emissions of the Cement Production Demystified: StepbyStep Process and 2016年3月1日 Saunders, A, ‘The highs and lows of India’s cement industry,’ Global Cement Magazine, March 2015; Saunders, A, ‘The cement industry of China ‘A new normal,’ Global Cement Magazine, JulyAugust 2015; Edwards, P ‘The rise and potential peak cement demand in the urbanized world,’ in Cornerstone, Volume 3, Issue 2, Summer 2015Coal for cement: Present and future trends Global Cement

Mining industry and sustainable development: time for change

2017年6月9日 Generally, the uranium ore extracted from the mine is processed by an associated mill order to obtain yellow cake (uranium oxide) for export (Fig 10) This mining and milling stage generates significant amounts of mining waste and radioactive waste tailings, where most of the radioactivity of uranium ore due to uranium radioactive daughters 2022年1月10日 The required pace of transition means that the availability of certain raw materials will need to be scaled up within a relatively short time scale—and, in certain cases, at volumes ten times or more than the current market size—to prevent shortages and keep newtechnology costs competitive (see sidebar “Rareearth metals”)The rawmaterials challenge: How the metals and mining 2024年2月23日 The operation of the cement raw mill is a critical step in cement production By grinding the raw materials into a fine powder, these powders can be more easily mixed with other cement ingredients and burn more evenly during the cement clinker process Therefore, the efficient operation of the cement raw mill directly impacts the production efficiency and quality How Does a Raw Mill Work in a Cement Industry2024年9月26日 Ask the Chatbot a Question Ask the Chatbot a Question cement, in general, adhesive substances of all kinds, but, in a narrower sense, the binding materials used in building and civil engineering construction Cements of this kind are finely ground powders that, when mixed with water, set to a hard massSetting and hardening result from hydration, which is a Cement Definition, Composition, Manufacture, History,