Cement Roller Mill For Sale Coal Russia

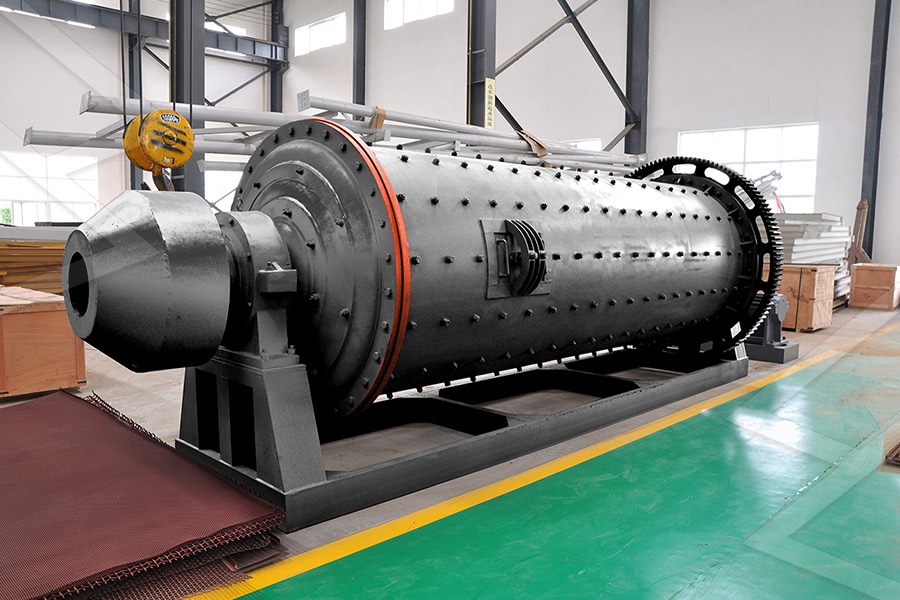

Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball Mill

Coal Mill in Cement Plant A coal mill is also called a coal pulverizer or coal grinder It is a mechanical device used to grind raw coal into pulverized coal powders The most used coal For more than 100 years, the Loesche GmbH has been developing and manufacturing vertical roller mills for grinding cement raw material, coal, clinker, granulated blast furnace slag and not just for the Russian market Cement Lime Gypsum ZKGVertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding material It VRM In Cement Plant Maximize Energy Saving CNBM 2017年8月12日 The speciallydeveloped hydraulic roller relief system enables grinding of different fuels (both hard and soft) and improves the machine control response Individual LOESCHEMILLS

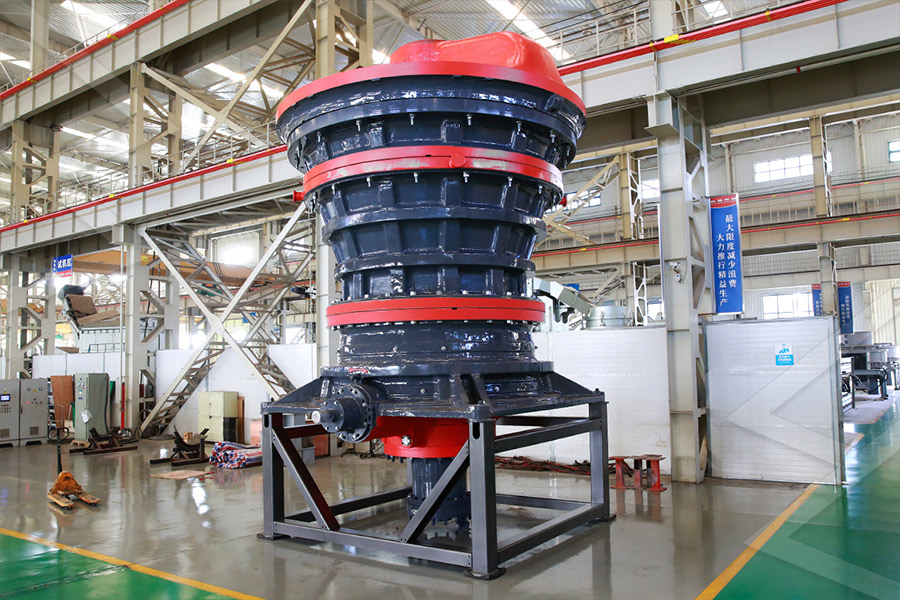

Vertical Roller Mill (VRM)SinomaLiyang Heavy

We can design and manufacture vertical roller mills of diversified specifications and models for raw meal, cement, and slag comminuation systems in cement clinker production lines with capacity up to 10,000t/dGebr Pfeiffer supplies innovative plant solutions for cement, coal, lime, gypsum and ceramics on which you can rely 100 % We only give our word if we know we can keep it And we keep what we have promised Extremely reliable and with Gebr Pfeiffer2016年3月1日 Similarly, in October 2014, Misr Beni Suef Cement announced plans to build a US$279m coal mill by the end of 2015 Next, in November 2014, Titan Cement ordered a Coal for cement: Present and future trends Global CementFind out all of the information about the Xinxiang Great Wall Machinery Co, Ltd product: roller mill GMRC Series coal mill Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of saleRoller mill GMRC Series coal mill Xinxiang

Vertical Roller Mill for Sale AGICO Cement Plant

AGICO Cement Technology manufactures advancing vertical roller mills for raw meal grinding, slag powder grinding, and cement grinding High grinding efficiency Low power consumptionvertical roller grinding mill LM series vertical for limestone for coal grinding Contact Output: 4 t/h 300 t/hVertical roller mill, Vertical roller grinding millThe most used coal mills in cement plants are airswept ball mills and vertical roller mills At present, most cement plants use coal as the main fuel in the clinker production process The standard coal consumed by the new dry process for producing 1 ton of cement clinker is usually between 100 kg and 130 kg, and the fuel cost accounts for Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball MillVertical roller mills (VRM) are a type of mainstream clinker grinding equipment in the cement manufacturing process Vertical roller mills are still newish cement mills since their history in cement production is no more than 20 years, but Vertical Roller Mill for Sale AGICO Cement Plant

.jpg)

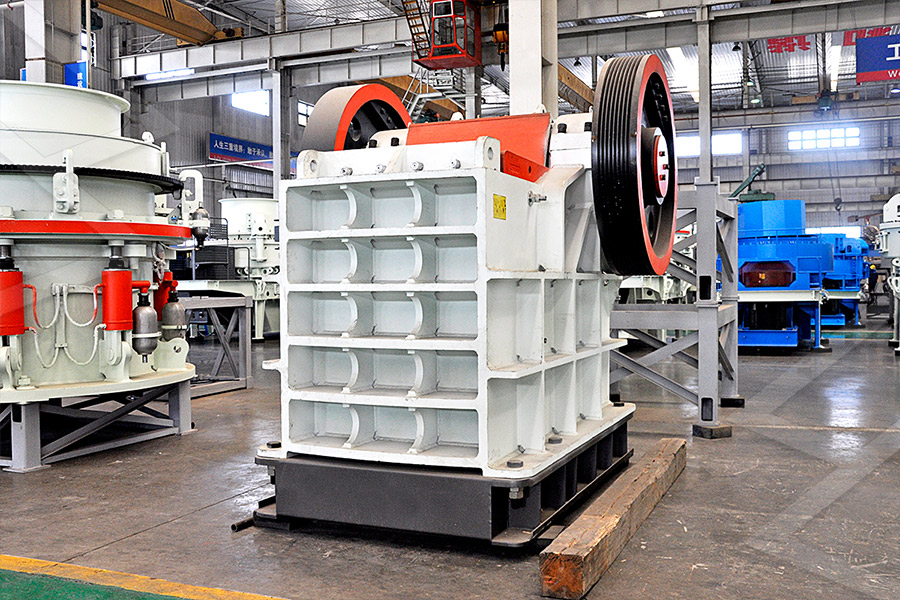

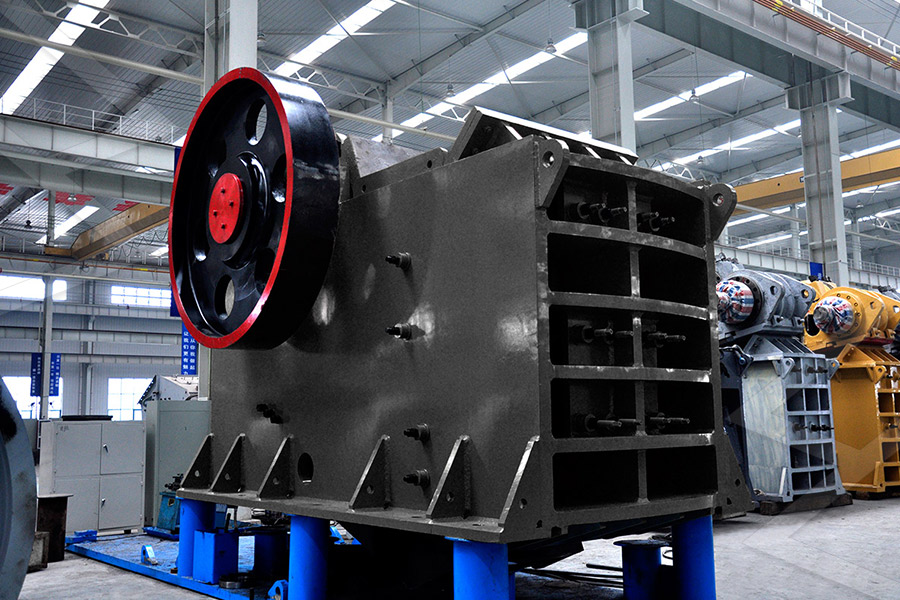

Cement Mill for Sale Buy Cement Ball Mill

Vertical Roller Mill Vertical roller mills (VRM) are a type of mainstream clinker grinding equipment in the cement manufacturing process Vertical roller mills are still newish cement mills since their history in cement production is no more 2016年3月1日 Similarly, in October 2014, Misr Beni Suef Cement announced plans to build a US$279m coal mill by the end of 2015 Next, in November 2014, Titan Cement ordered a Gebr Pfeiffer SE type MPS 2800 BK vertical roller mill for coal Coal for cement: Present and future trends Global CementAdvantages of cement ball mill Less investment: cement ball mill with advantages of a perfect motor system, low energy consumption and power consumption, and ultralow operating cost, which can save a lot of cost input; Good working environment: reasonable sealing, less dust, low noise, good production environment; Costeffective: the price of the cement ball mill is Cement Ball Mill Ball Mill For Sale Cement Mill 15100t/hThis is where vertical roller mill technology comes in Vertical roller mill (VRM) is a grinding machine that has revolutionized the cement industry by enabling efficient and ecofriendly cement production This article will explore the application of vertical roller mills in the cement industry, including their benefits, efficiency, and eco Application of Vertical Roller Mill in Cement Production

.jpg)

Cement Manufacturing Equipment for Sale AGICO Cement

Mini Cement Plant Hot Sale; Cement Plant 700 ~ 2000tpd; Cement Plant 2500~7000tpd; Coal Mill; Clinker Calcination Menu Toggle Cyclone Preheater; Rotary Cement Kiln; Grate Cooler; Rotary Cooler; Cement Grinding Menu Toggle Hydraulic Roller Press; High Pressure Grinding Roll; Cement Mill; Vertical Roller Mill; Cement Mill Separator; Steel Today, we continue to use our curiosity and innovative approach to discover new ways to optimise equipment and processes We are especially active in bringing the advantages of digitalisation to the cement industry Our experience in automating cement plants has given us a head start on harnessing the potential of digital technologiesPremium solutions for the cement industry FLSmidthVertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as cement, electric power, metallurgy VRM In Cement Plant Maximize Energy Saving CNBM Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by Raw mill Cement Plant

Cement Roller Press Roller Press In Cement

Semifinishing grinding system: after ground by cement roller press, materials are divided into three parts through an air classifier: coarse, medium and fine, in which the coarse material is returned to the roller press for regrinding, the 2024年3月22日 AGICO CEMENT INTERNATIONAL ENGINEERING CO, LTD is an experienced ball mills supplier, that provides types of ball mills, vertical roller mills, rod mills, and AG/SAG mills for cement, mining, chemical, and electric Ball Mill for Sale Cement Mining and Chemical 6 天之前 A vertical roller mill is an energysaving mill that meets market demand It has a low operating cost and highcost performance Presale service Sales service Aftersales service the most popular types of Energysaving and Efficient Vertical Roller MillThe grinding media balls in the ball mill are used in cement plant to help grind blocky or granular grindable materials produced in the cement manufacturing process, so as to achieve the effect of grinding Vertical roller mill(VRM) and clinker grinding mill and other cement grinding mill are also very common in cement plantBall Mill for Sale Mining and Cement Milling Equipment

(PDF) Performance Evaluation of Vertical Roller Mill in Cement

2017年9月11日 A conventional cement grinding circuit is composed of a two compartment tube mill, a mill filter which collects the fine material inside the mill and a dynamic air separator where final product 2021年9月13日 Specializing in the sale of second hand cement plant equipment, and complete used cement plants In addition to used and new surplus Cement Plant Equipment (rotary kilns, ball mills, vertical roller mills), NMI deals in many other types of machinery, including used equipment for Bulk Material Handling, Crushing, Grinding, Industrial Mineral Processing, and Nelson Machinery International Sellers of SecondHand Cement The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unit Advantages of the MPS vertical mill MPS 3070 BK coal mill, Jaypee Cement Balaji, India MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsBenefits of AGICO mini cement plant Lower investment: compared to a largesized cement manufacturing plant, the mini cement plant requires less capital investment per ton of cement production; High flexibility: less cement plant equipment and a smallscale cement production line makes the whole mini cement plant more flexible; Less area occupied: mini cement plant Mini Cement Plant For Sale Mini Cement Plant Cost AGICO

.jpg)

How Does a Raw Mill Work in a Cement Industry

2024年2月23日 The operation of the cement raw mill is a critical step in cement production By grinding the raw materials into a fine powder, these powders can be more easily mixed with other cement ingredients and burn more evenly during the cement clinker process Therefore, the efficient operation of the cement raw mill directly impacts the production efficiency and quality Cementos Cibao SA, cement producer in the Dominican Republic, continues the modernization process and ordered a cement mill type QMC² 40/20 for grinding different cement types Compact plant arrangement with service tower, quadropol® thyssenkrupp Polysius Grinding Ball mill liner or ball mill linning is lined with ball mill barrel, to protect the wall of ball mill barrel from being damaged by the impact of material and steel balls At the same time, the movement state of the grinding medium in the barrel can Ball Mill Liner For Sale – Custom DesignFind your vertical roller mill easily amongst the 14 products from the leading brands (FLSmidth DorrOliver Eimco, FLSMIDTH, ) on DirectIndustry, the industry specialist for your professional purchases operation and Vertical roller mill, Vertical roller grinding mill

.jpg)

A Comprehensive Guide to Finding the Best Ball Mill for Sale

Factors to Consider When Buying a Ball Mill for Sale When you’re shopping for a ball mill for sale, there are several factors to consider to ensure you choose the best machine for your needs Some key factors include: Capacity: The capacity of the mill will determine how much material it can process at once Be sure to choose a machine with The Raymond bowl type ring mill [148] for coal dryinggrinding is widely used in the American cement industry This mill has all the characteristic features of the roller mills described above; it consists essentially of a replacable grinding ring, carried by a rotating grinding bowl and an opencircuit ball mill with a throughput of 150 t Roller mills INFINITY FOR CEMENT EQUIPMENTAGICO Cement is a professional and experienced supplier in offering cement equipment and cement production linesIn addition to providing customers with a complete set of cement equipment, we also provide customers with various cement machinery accessories, such as dust collector filter bag, filter bag cage, kiln tyre, kiln support roller, ball mill hollow shaft, girth gear, Cement Plant Spare Parts For Sale AGICO Cement Vertical coal grinding mill integrates crushing, drying, grinding, powder selection and conveying; It has simple system and compact structure Vertical coal mill covers an floor area about 50% of the coal ball mill with the same specification; Coal vertical mills can work in openair environments, greatly reducing the cost of investment The design of the vertical coal mill system is simple Vertical Coal Mill for Coal Grinding in Cement Plant Power

OK™ Raw and Cement Mill FLSmidth Cement

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeWhat Is Air Swept Coal Mill The airswept coal mill is also called a coal grinder It is the main equipment of the cement plant, used for drying and pulverizing coal powderIt mainly consists of the feeding device, main bearing, rotary part, transmission device, discharging device, highpressure starting device, and lubrication systemAir Swept Coal Mill Coal Mill In Cement Plant AGICO GROUP2024年9月11日 Type: Vertical Roller Mill Motor Type: AC Motor Motor Power: 135kw Rotationl Speed: 1315r/min Application: Mine Materials: Coal, Slag, Flyash, Cement, Calcium CarbonateFlyash Slag Calcium Carbonate Cement Coal Vertical Roller Mill The most used coal mills in cement plants are airswept ball mills and vertical roller mills At present, most cement plants use coal as the main fuel in the clinker production process The standard coal consumed by the new dry process for producing 1 ton of cement clinker is usually between 100 kg and 130 kg, and the fuel cost accounts for Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball Mill

.jpg)

Vertical Roller Mill for Sale AGICO Cement Plant

Vertical roller mills (VRM) are a type of mainstream clinker grinding equipment in the cement manufacturing process Vertical roller mills are still newish cement mills since their history in cement production is no more than 20 years, but Vertical Roller Mill Vertical roller mills (VRM) are a type of mainstream clinker grinding equipment in the cement manufacturing process Vertical roller mills are still newish cement mills since their history in cement production is no more Cement Mill for Sale Buy Cement Ball Mill2016年3月1日 Similarly, in October 2014, Misr Beni Suef Cement announced plans to build a US$279m coal mill by the end of 2015 Next, in November 2014, Titan Cement ordered a Gebr Pfeiffer SE type MPS 2800 BK vertical roller mill for coal Coal for cement: Present and future trends Global CementAdvantages of cement ball mill Less investment: cement ball mill with advantages of a perfect motor system, low energy consumption and power consumption, and ultralow operating cost, which can save a lot of cost input; Good working environment: reasonable sealing, less dust, low noise, good production environment; Costeffective: the price of the cement ball mill is Cement Ball Mill Ball Mill For Sale Cement Mill 15100t/h

.jpg)

Application of Vertical Roller Mill in Cement Production

This is where vertical roller mill technology comes in Vertical roller mill (VRM) is a grinding machine that has revolutionized the cement industry by enabling efficient and ecofriendly cement production This article will explore the application of vertical roller mills in the cement industry, including their benefits, efficiency, and eco Mini Cement Plant Hot Sale; Cement Plant 700 ~ 2000tpd; Cement Plant 2500~7000tpd; Coal Mill; Clinker Calcination Menu Toggle Cyclone Preheater; Rotary Cement Kiln; Grate Cooler; Rotary Cooler; Cement Grinding Menu Toggle Hydraulic Roller Press; High Pressure Grinding Roll; Cement Mill; Vertical Roller Mill; Cement Mill Separator; Steel Cement Manufacturing Equipment for Sale AGICO Cement Today, we continue to use our curiosity and innovative approach to discover new ways to optimise equipment and processes We are especially active in bringing the advantages of digitalisation to the cement industry Our experience in automating cement plants has given us a head start on harnessing the potential of digital technologiesPremium solutions for the cement industry FLSmidthVertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as cement, electric power, metallurgy VRM In Cement Plant Maximize Energy Saving CNBM

Raw mill Cement Plant

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by