Centerless Grinding Process Bauxite Classifier Machine

Roundness prediction in centreless grinding using physics

2020年12月8日 Complexity in centreless grinding models arises from phenomena like contact length dependency on local compliance, contact force and grinding wheel roughness, Centerless grinding is a machining process characterized by highly nonlinear dynamics and large model uncertainty, making it difficult to predict the quality ofA semisupervised physicsinformed classifier for centerless grinding 2012年1月1日 The paper presents the stateoftheart centerless grinding technologies: advanced machines, advanced process monitoring and the latest developments in grinding Advances in centerless grinding technology ScienceDirect2007年1月1日 To introduce vibrations in the model, the dynamic flexibility of the machine H(s) may be used Centerless grinding process is usually well defined with a two dimensional Intelligent Centerless Grinding: Global Solution for Process

.jpg)

Geometrical optimization of centerless grinding process by

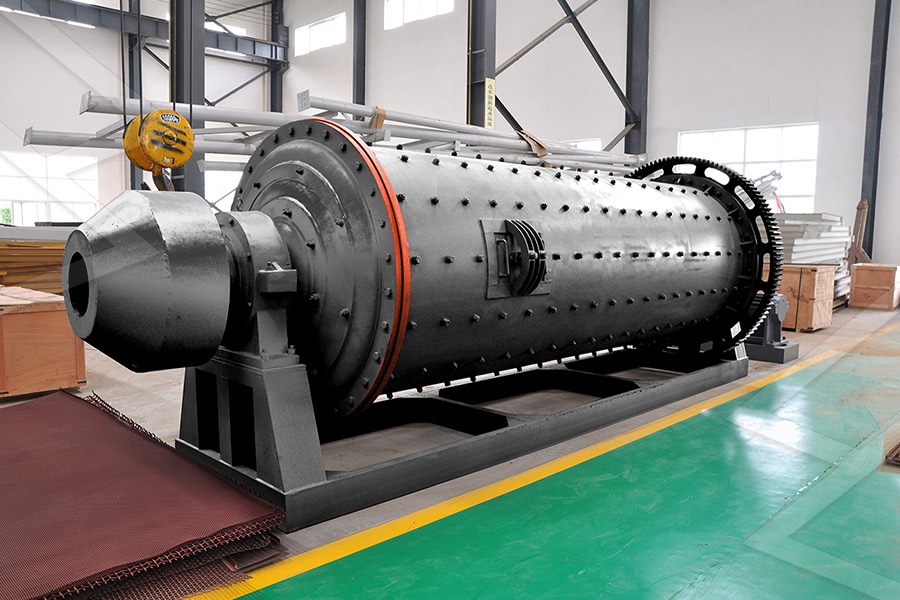

2021年4月20日 In the track of the abovementioned work, this paper presents a solution to change rapidly workrest angle and WP height It is based on the adoption of a profiled 2015年7月1日 In this work, we present a hybrid ball mill model and a spiral classifier model for the grindingclassification process of bauxite, where the material characteristics and operation Hybrid modeling of an industrial grindingclassification process2022年1月23日 The most common process step to feed an alumina refinery with bauxite is sizing of the raw bauxite material that is extracted from the mine The first crushing of the Physical Bauxite Processing: Crushing and Grinding of BauxiteCompact and highly rigid machine with concrete bed High positioning accuracy with linear guide system for table movement Grinding wheel size: Φ610mm x width 125mmCenterless grinding machines CLG series

A semisupervised physicsinformed classifier for centerless grinding

2022年8月25日 Centerless grinding is a machining process characterized by highly nonlinear dynamics and large model uncertainty , making it difficult to predict the quality of the worked 2016年12月1日 The Machine Centerless grinding machines are often classified according to the inclination of the machine bed Horizontalbed machines are the most common, as they provide easy accessibility during wheel dressingBasics of centerless grinding Cutting Tool 2021年2月23日 3 Endfeed Centerless Grinding You have to adopt the endfeed centerless grinding for a workpiece with a head and a tapered diameter However, for doing this, the grinding wheel or both the grinding wheel and the What is Centerless Grinding? How Does the Phone: 5865415300 : sales@totalgrindingsolutions Total Grinding Solutions Inc 13265 East 8 Mile Road Warren, Michigan, USA 48089Centerless Grinding Machines Total Grinding Solutions

.jpg)

Centerless Grinding Machines Glebar

The GT610 Automated Infeed/Thrufeed Centerless Grinding Machine can be custom fitted with automation This system is the ideal option for when infeed applications do not require a CNC dresser and for the vast majority of thrufeed 2017年2月15日 The centerless process is commonly used for high volume production, and it’s also easily used for low volume production because the machine setups are fairly simple In thrufeed centerless OD grinding the workpiece passes between two wheels, a grinding wheel and a regulating wheel (as illustrated in the diagram seen here)Thrufeed Centerless OD Grinding: Parameters and Troubleshooting2016年12月1日 Dual grinding machines deliver a twostep process that combines centerless grinding with grinding between centers, alleviating concentricity concerns In the Zone Regardless of machine design, the workpiece is guided by its outer surface during centerless grinding Because of this, roundness can be a concern, especially lobing and triangulationBasics of centerless grinding Cutting Tool Engineering5 天之前 A centerless grinding and polishing machine is a specialized tool used in manufacturing processes to grind and polish cylindrical workpieces Skip to the content The centerless grinding process typically involves the following steps: Workpiece Feeding: The workpiece, often in the form of a long rod or tube, is fed into the grinding machine Centerless Grinding and Polishing Machine Metal Surfaces

.jpg)

Acme Centerless Grinding Machines Acme Manufacturing

2024年10月2日 Acme’s Centerless Grinding Finishing Processes Heavy stock removal for rough OD belt grinding can achieve 030” 060” (075mm to 15mm) Tolerance grinding/sizing from 3 to 100 feet per minute (FPM) (10 to 300 meters per minute)Centerless grinding machines Estarta was born in the 20th century, and it brings out its best in the 21st A completely renewed range that’s faithful to its core grinding concepts (including precision, stiffness, and thermal stability) yet still brings together all the innovations of recent years (eg userfriendliness)Centerless grinding machines DanobatThe Centerless Grinding Process Having established what centerless grinding is, let's delve into the mechanics of the process Centerless grinding involves three primary components: the grinding wheel, the regulating wheel, and the workpiece rest blade The dance between these three elements is what makes the magic happen The Grinding WheelCenterless Grinding Explained: Precision Machining for High 2016年12月8日 The centerless grinding process is deceptively simple yet precise the two most commonly used methods of precision centerless grinding is in how the workpieces are fed through the machine Throughfeed grinding is typically used for parts with consistent roundness across the length of the part In this method, the workpiece travels along 8 Principles of Precision Centerless Grinding

What is Centerless Grinding? Process,

2024年5月3日 What is Centerless Grinding? Centreless is an Accurate Grinding method that removes the chips, burrs, marks, and cuts to specific dimensions without any fixed positioning like spindle mounting The main difference is in Centerless grinding machines CLG series > Product List Trusted bestselling machine Proven Brand CLG Series In 1952, we began production of the CLG2 model, the prototype of the later bestselling CLG2BII, which was highly Centerless grinding machines CLG series2022年1月23日 The following bauxite grinding circuits are the main circuits employed in the alumina industry today Rod/Ball Mill—Open Circuit This is probably the most common grinding mill type and has been used for over 40 years It is often the base case considered for bauxite grinding The mill is operated in open circuit and comprises two compartmentsPhysical Bauxite Processing: Crushing and Grinding of BauxiteMichigan's Top Centerless Grinders With centerless grinders, a workpiece supported by a work rest blade is set between a rotating grinding wheel and a rubber regulating wheel that rotates the workpiece Koyo remains a world leader in centerless grinder technology by delivering reliability, high accuracy, and improved grinding efficiencyCenterless Grinders: Finishing Grinding Machines Koyo

Centerless Grinding Introduction, Advantages, And Application

2020年10月8日 Types of Centerless Grinding Process There are three types of centerless grinding The main difference lies in the method of feeding the workpiece through the machine tool Infeed Grinding The workpiece can have an independent outer diameter over the entire length, and the improved grinding wheel can be used to grind each part of the 6 天之前 This process can be categorized into two types: external centerless grinding and internal centerless grinding While external centerless grinding is widely used for finishing the outer surfaces of workpieces, internal centerless grinding is employed for specialized applications, such as creating smooth internal holes for shafts There are also Centerless Grinding: Process, Types, and Key AdvantagesCenterless Grinding Machines teaser250 Minimum Diameter(mm): 1 Maximum Diameter(mm): 50 Grinding Wheel(mm): 455 x 150 x 2286 Regulating Wheel(mm): 230 x 150 x 1016 Length(mm): 150 Machine Dimensions(mm): 2500 x 1100 x 1850 Machine Weight(kg): 3000 MPC450IIGS Compatible with 8 inch (205 mm) wide whetstones! A centerless grinder Centerless Grinders Micron USACenterless grinding is the process of removing material from the outside diameter of a work piece using an abrasive wheel In its simplest form, a centerless grinder consists of the machine base, grinding wheel, regulating wheel and work blade With centerless grinding, the work piece is not mechanically held to drive the partCENTERLESS GRINDING PROCESS Total Grinding Solutions

COMPANY PROFILE Centerless Grinding Machines NISSIN MACHINE

Developed a fully automated machine with inprocess and post process gauges 1974: Added Engineering Service Division and expanded rebuilding business, and customers service As a Centerless Grinding Machine, HIGRIND 2 is the first model awarded by them HIGRIND 2 model, awarded is developed to aim higer accuracy, higher productivity and 2020年12月8日 This work proposes a model for suggesting optimal process configuration in plunge centreless grinding operations Seven different approaches were implemented and compared: first principles model, neural network model with one hidden layer, support vector regression model with polynomial kernel function, Gaussian process regression model and Roundness prediction in centreless grinding using physics At the EMO in Hanover the APGS DT is exhibited, the first centerless grinding machine in the World with the new CNC Siemens SINUMERIK ONE for the creation of its Digital Twin 2021 On September 12th 2021 the company celebrated its 100th anniversary and to celebrate this important milestone it has presented a new line of centerless grinding Centerless grinding machines UltraPrecision and High2024年10月4日 Centerless grinding is a precise and efficient machining process used to remove material from a workpiece without the use of a grinding machine This process is ideal for cylindrical and bar grinding, resulting in an excellent The Ultimate Guide to Centerless Grinding in

Master Centerless Grinding: Tips for TroubleFree Operation

2017年5月8日 If your machine is equipped for stationary tooling, make certain to use a highquality dress nib Relatively quick, light passes are most effective, and 812 ipm @ 00005″0001″ depth of cut is a good place to start contact the Norton SaintGobain Abrasives Application Engineering Team to improve your centerless grinding process or Total Grinding Solutions Is Open for Business Total Grinding Solutions (TGS) is a worldwide manufacturer of CNC centerless grinders With more than 150 years of combined industry experience, TGS engineers, designs and builds precise, affordable and reliable centerless grinding machines that offer quick payback and low cost of ownershipTotal Grinding Solutions2024年4月18日 Choosing the right centerless grinder machine is essential for optimal grinding performance Consider these 5 key factors to make an informed decision 899 Sheridan Dr, West Chester, Pennsylvania Setup: Before starting the centerless grinding process, the machine must be properly set up This involves adjusting the position and alignment of 5 Key Considerations When Choosing A Centerless Grinder Machine2023年5月18日 A centerless grinding machine is a machine tool that uses CNC technology to grind the surface of a workpiece using grinding tools Most grinders use highspeed rotating grinding wheels for grinding, while a few use other grinding tools such as oilstones, abrasive belts, and free abrasives for processing, such as honing machines, ultraprecision machining Guide to Centerless Grinding Machine: Advantages, Working

.jpg)

Centerless Grinding Plunge Grinding or InFeed

Grinding machines have the ability to grind multiple diameters in complex parts of different sizes in one plunge only This also involves part’s complex radii and angles The plunge grinding centerless grinding process comes into play if one needs to grind extremely complex parts in machining automotive parts and componentsGlebar partners with its customers to achieve a complete solution that focuses on continuous improvement and ROI Glebar’s machines are well represented across all industries around the globe manufacturing grinding solutions such as double disc grinders, form grinders, OD grinders, micro grinders, gauging systems, burr free ECG cutoff and grinding machines, and Centerless BurrFree ECG Grinding Machines GlebarA centerless grinder is a type of grinding machine that performs precision grinding on cylindrical workpieces without the need for centers or chucks It offers advantages such as increased productivity, superior roundness and surface finish, and the ability to handle a wide range of workpiece diametersCenterless Grinder SUPERTEC MACHINERY, INC2020年8月20日 where ‘b’ is the width of the disc, ‘r’ is the radius of the disc, ‘F N ’ is the normal force applied to the disc over the grinding wheel, ‘a’ is the gradient of the characteristic curve of grinding wheel, ie regression line obtained from the plot of ‘displacement’ versus ‘t (2/3) ’ A device used for measuring the grinding wheel sharpness has been designed and Acoustic EmissionBased Grinding Wheel Sharpness

What is Centerless Grinding? How Does the

2021年2月23日 3 Endfeed Centerless Grinding You have to adopt the endfeed centerless grinding for a workpiece with a head and a tapered diameter However, for doing this, the grinding wheel or both the grinding wheel and the Phone: 5865415300 : sales@totalgrindingsolutions Total Grinding Solutions Inc 13265 East 8 Mile Road Warren, Michigan, USA 48089Centerless Grinding Machines Total Grinding SolutionsThe GT610 Automated Infeed/Thrufeed Centerless Grinding Machine can be custom fitted with automation This system is the ideal option for when infeed applications do not require a CNC dresser and for the vast majority of thrufeed Centerless Grinding Machines Glebar2017年2月15日 The centerless process is commonly used for high volume production, and it’s also easily used for low volume production because the machine setups are fairly simple In thrufeed centerless OD grinding the workpiece passes between two wheels, a grinding wheel and a regulating wheel (as illustrated in the diagram seen here)Thrufeed Centerless OD Grinding: Parameters and Troubleshooting

.jpg)

Basics of centerless grinding Cutting Tool Engineering

2016年12月1日 Dual grinding machines deliver a twostep process that combines centerless grinding with grinding between centers, alleviating concentricity concerns In the Zone Regardless of machine design, the workpiece is guided by its outer surface during centerless grinding Because of this, roundness can be a concern, especially lobing and triangulation5 天之前 A centerless grinding and polishing machine is a specialized tool used in manufacturing processes to grind and polish cylindrical workpieces Skip to the content The centerless grinding process typically involves the following steps: Workpiece Feeding: The workpiece, often in the form of a long rod or tube, is fed into the grinding machine Centerless Grinding and Polishing Machine Metal Surfaces2024年10月2日 Acme’s Centerless Grinding Finishing Processes Heavy stock removal for rough OD belt grinding can achieve 030” 060” (075mm to 15mm) Tolerance grinding/sizing from 3 to 100 feet per minute (FPM) (10 to 300 meters per minute)Acme Centerless Grinding Machines Acme ManufacturingCenterless grinding machines Estarta was born in the 20th century, and it brings out its best in the 21st A completely renewed range that’s faithful to its core grinding concepts (including precision, stiffness, and thermal stability) yet still brings together all the innovations of recent years (eg userfriendliness)Centerless grinding machines Danobat

.jpg)

Centerless Grinding Explained: Precision Machining for High

The Centerless Grinding Process Having established what centerless grinding is, let's delve into the mechanics of the process Centerless grinding involves three primary components: the grinding wheel, the regulating wheel, and the workpiece rest blade The dance between these three elements is what makes the magic happen The Grinding Wheel2016年12月8日 The centerless grinding process is deceptively simple yet precise the two most commonly used methods of precision centerless grinding is in how the workpieces are fed through the machine Throughfeed grinding is typically used for parts with consistent roundness across the length of the part In this method, the workpiece travels along 8 Principles of Precision Centerless Grinding